Usually the phrase “power brick” refers affectionately to the AC adapter of something like a laptop. But what if that term was quite literal, involving an actual brick?

A team led by Hongmin Wang at Washington University in St. Louis set out to make a genuine power brick. More specifically, they wanted to see if they could use a vapor coating technique to turn ordinary red bricks into part of a supercapacitor. That actually isn’t quite as weird as it sounds, given that the red of a brick is an iron mineral, and iron is a common component of some battery chemistries. Bricks are often porous as well, meaning there is plenty of surface area where a thin coating could interact with that iron.

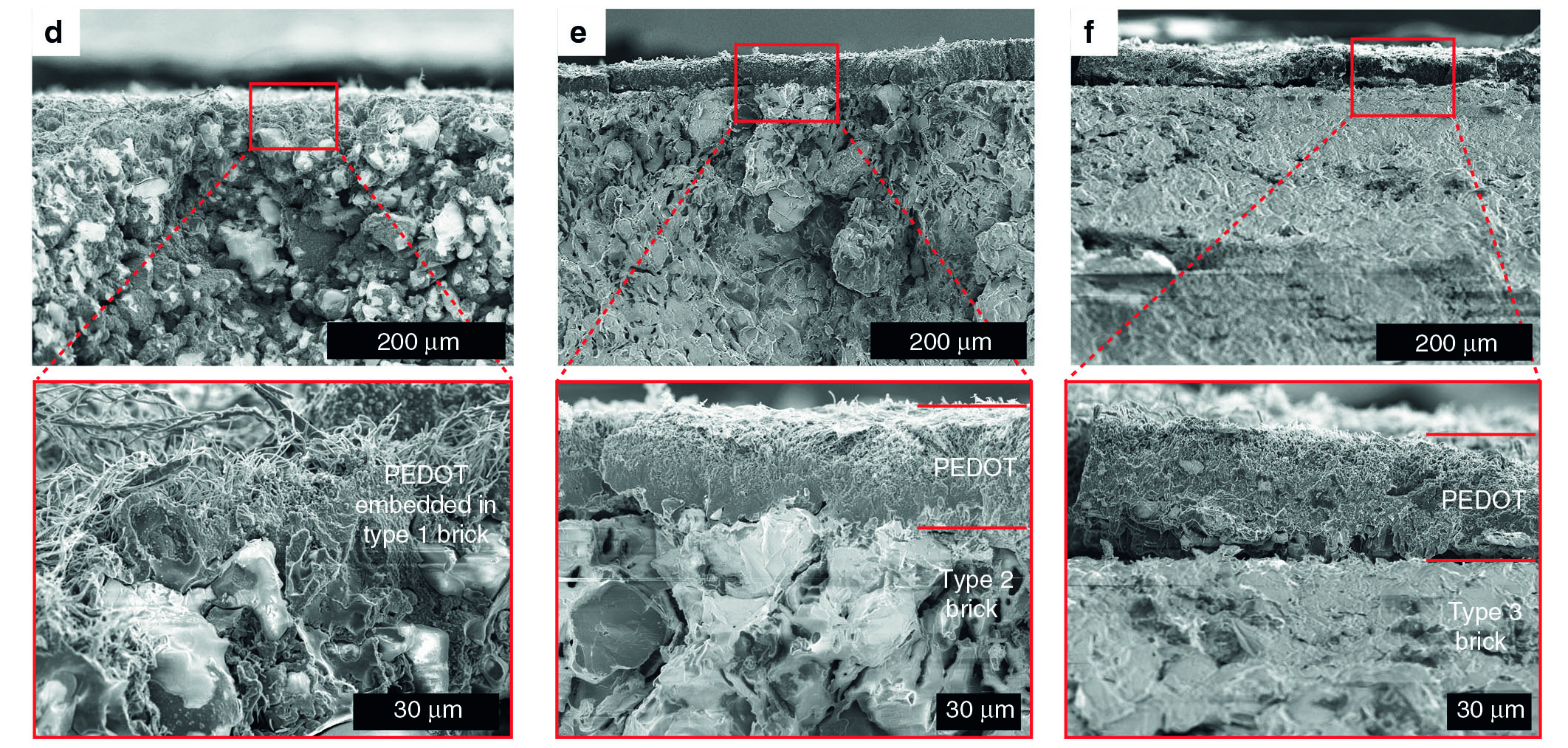

The process (something they had developed previously) involves heating the brick in an enclosure along with hydrochloric acid and an organic compound that mercifully shortens to “EDOT.” The two liquid substances evaporate and condense on the brick’s convoluted surface. The acid dissolves some of the iron mineral, freeing up iron atoms that help the organic molecules link up to form polymer chains (graduating to “PEDOT”) that coat the surface. The polymer makes microscopic, entangled fibers that form a continuous and electrically conductive layer on each face of the brick, which otherwise remains. (This does have the effect of turning the brick black, though.)

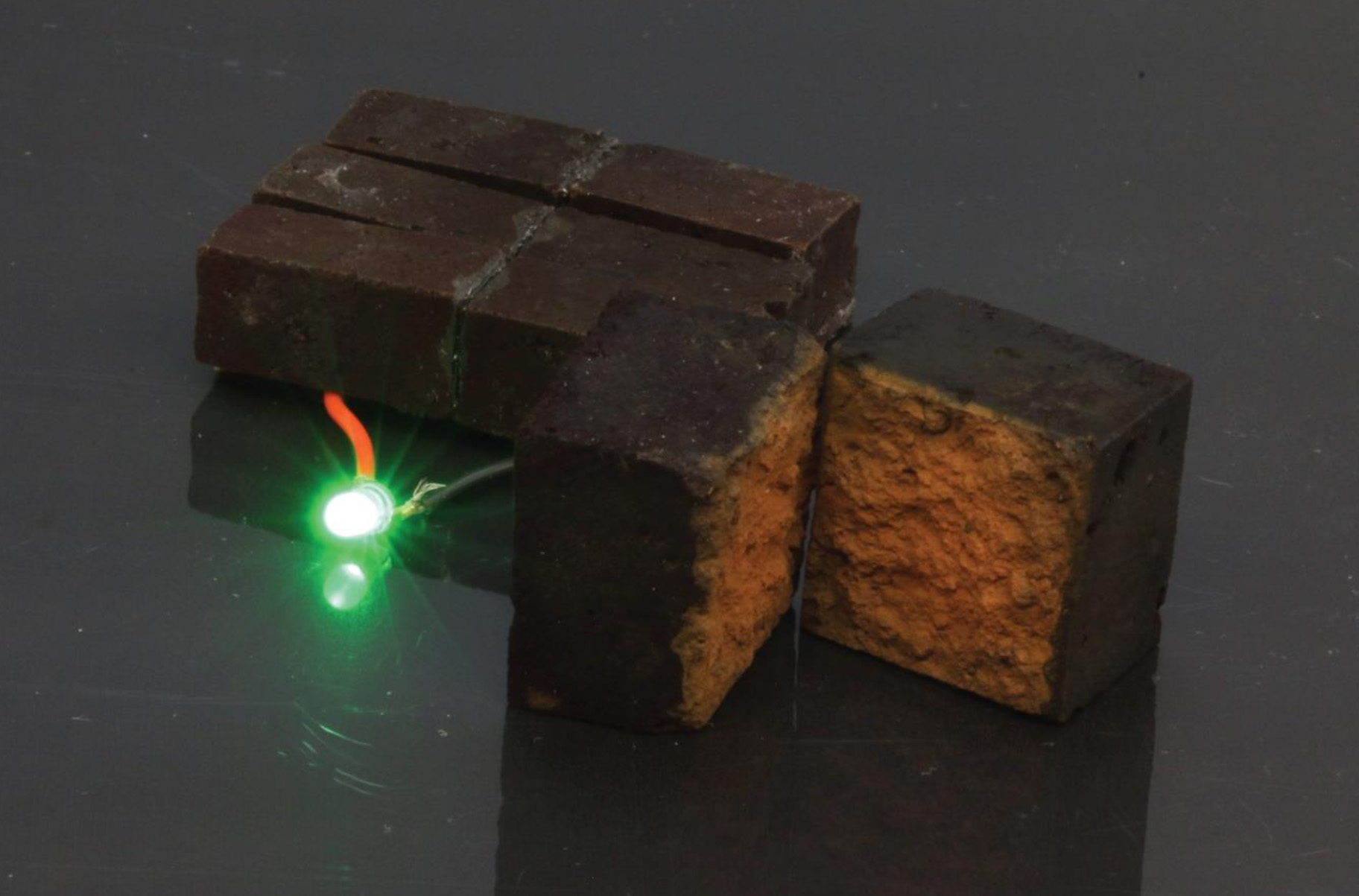

The team tested performance in a couple of configurations, including one with a sturdy gel electrolyte sandwiched between the bricks like mortar. Coating the whole thing in epoxy makes it waterproof (as in, "works underwater" waterproof) and also prevents the electrolyte from ever drying out. Many combinations of bricks connected in series and parallel are obviously possible, although for testing they wired three units of tiny sugar-cube-sized bricks in series. After fully charging in 15 seconds, this configuration powered an LED for about 11 minutes before the voltage dropped from the initial 2.7 volts to below the LED’s required 2.5 volts.

Even with full-size bricks, the total energy storage is… less than huge. They estimate that a wall of these bricks could hold about 1.6 watt-hours per square meter of wall area. That means a three meter by six meter (10 feet by 20 feet) wall could hold about 20 watt-hours of electricity. As a result, the researchers’ pitch for this idea is less dramatic than “turn your house into a battery!”

“Our supercapacitor technology adds value to a ‘dirt-cheap’ construction material and demonstrates a scalable process affording energy storage for powering embedded microdevices in architectural applications that utilize fired brick,” they write. These powered walls probably won’t be challenging Tesla’s Powerwall (13.5 kilowatt-hours in less than a square meter on the wall) any time soon. But it’s a creative concept—a supercapacitor brick definitely wouldn’t be just another brick in the wall.

Nature Communications, 2020. DOI: 10.1038/s41467-020-17708-1 (About DOIs).

reader comments

115